Mirror, Mirror...Casting 2 Massive, Matching, Monolithic Concrete Coffee Tables in Brooklyn

William McIntosh Design, is a New York City based interior design and decoration firm led by award-winning designers William McIntosh and Martin Raffone. The partners create sophisticated interiors that are individually conceived, refined and meticulously crafted, forging a perfect balance between timelessness and today.

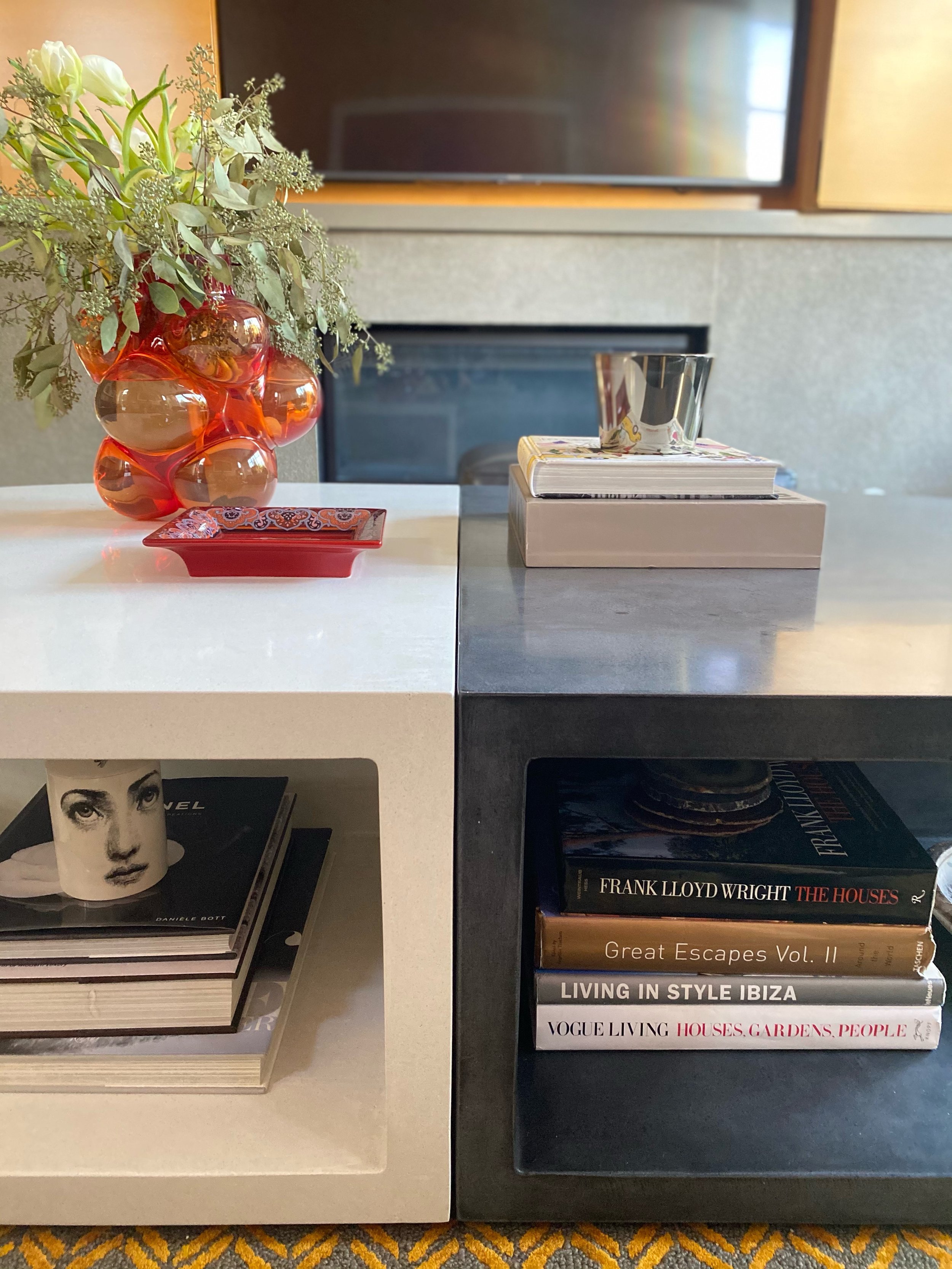

When William and his team approached us earlier this year, they were working on a project for a Brooklyn-based client that would be completed before the end of the year. In our initial discussions, they mentioned to us how they were looking to create two perfectly-mirrored, massive & monolithic coffee tables out of concrete - one in white, the other in black. The two tables, they told us, would eventually be positioned back to back, forming a full oval shape, and set inside the living room of a luxurious, sophisticated interior.

While on the surface, this may seem like any other custom concrete fabrication job, there were numerous precise calculations and nuanced considerations that had to be taken into account in order for this project to be successful.

Since the two pieces had to be individually fabricated, we were forced to get creative with the mix of concrete and structural support that we chose to put in place. The whole piece was cast in solid concrete, even though each half weighs around 500 lbs! Despite this massive size, we still needed the top of the table to be self-supporting and cantilevered at the edges, forming a sort of “T-shape” in order to deliver on the desired design specs.

To make sure the piece did not crack in the center, we had to come up with a reinforcement solution. Here we used a specific type of fiber reinforcement in the concrete mix that allowed us to pour each side as a single, giant pour without having to use any steel inside.

The client’s main concern was making sure that each of the two sides were exactly like the other and that they would meet with a zero tolerance seam (basically, the pieces needed to be perfectly symmetrical). This involved a series of drawings, mock-ups and general back and forth internally to ensure that we delivered on our promises. I must say, this wasn’t easy given how big the pieces were but in the end, we’re really glad with how everything turned out!